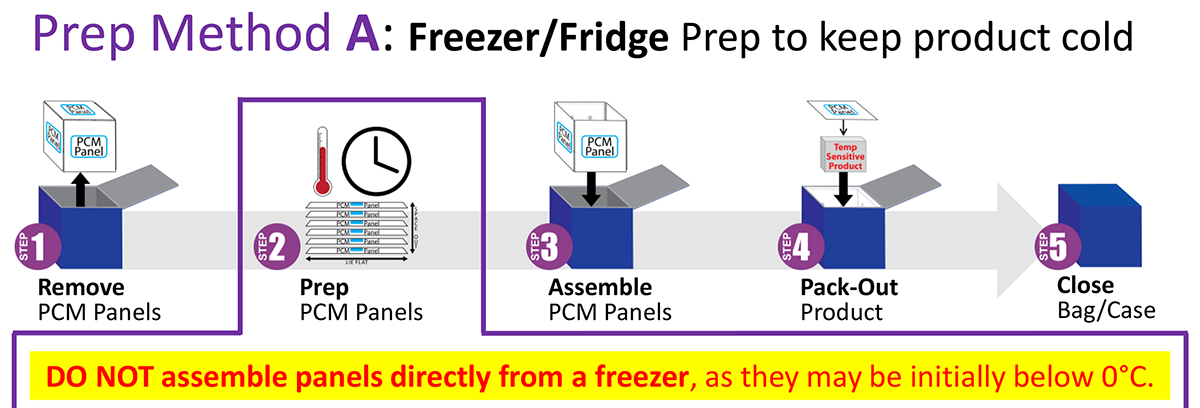

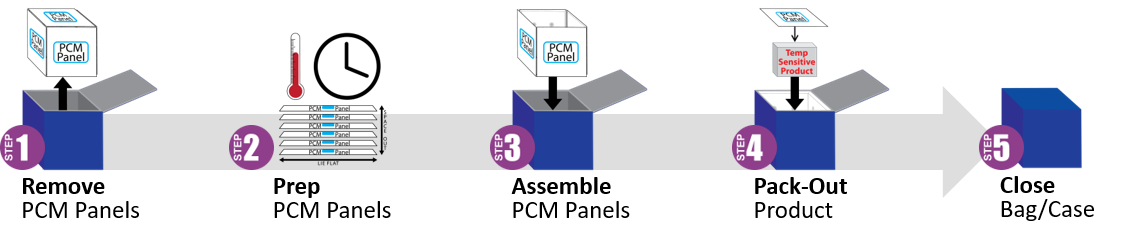

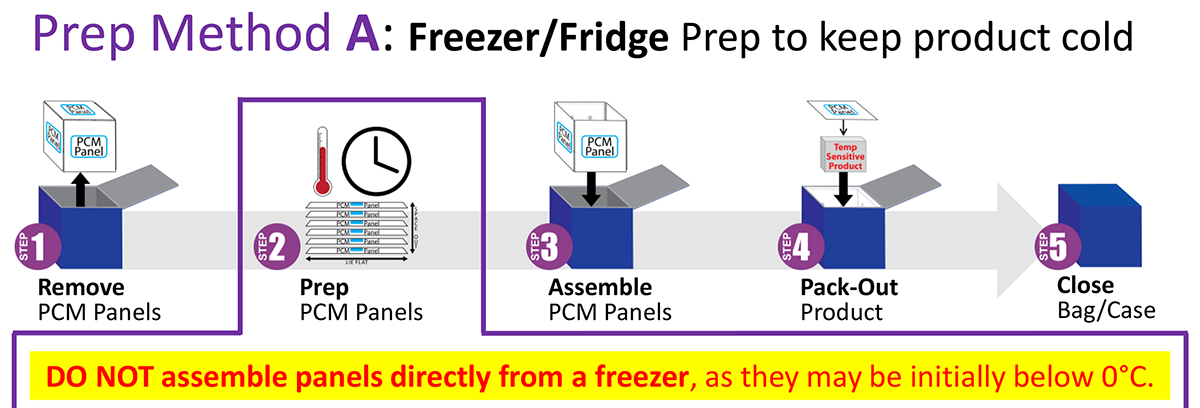

Refrigerated 4 Prep Method A: Freezer to Fridge Pack-Out Instructions

Panel Prep

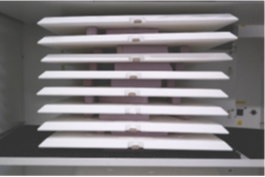

2.1 Lay panels flat in a freezer until all the PCM (phase change material inside the panel) turns solid. At -15°C/5°F the PCM will solidify in a couple hours.

2.2 Transfer panels into a fridge at least 3 hours before use. Panels may be stored in the fridge until needed for assembly or until the PCM melts.*

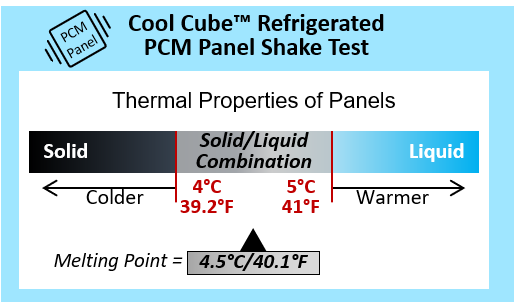

* If a fridge maintains 4°C/39°F or below, the PCM within the panels will not melt (melting point is 4.5°C/40°F), which will keep the panel solid indefinitely until pack-out. If the fridge maintains 5°C/41°F or above, periodically check for melting and restart at step 2.1 to ensure optimal performance.

2.3 Shake panels to verify the PCM is solid. If there is liquid, restart at step 2.1 to ensure the longest hold time. Using liquid PCM or panels with a solid/liquid combination decreases the hold time.

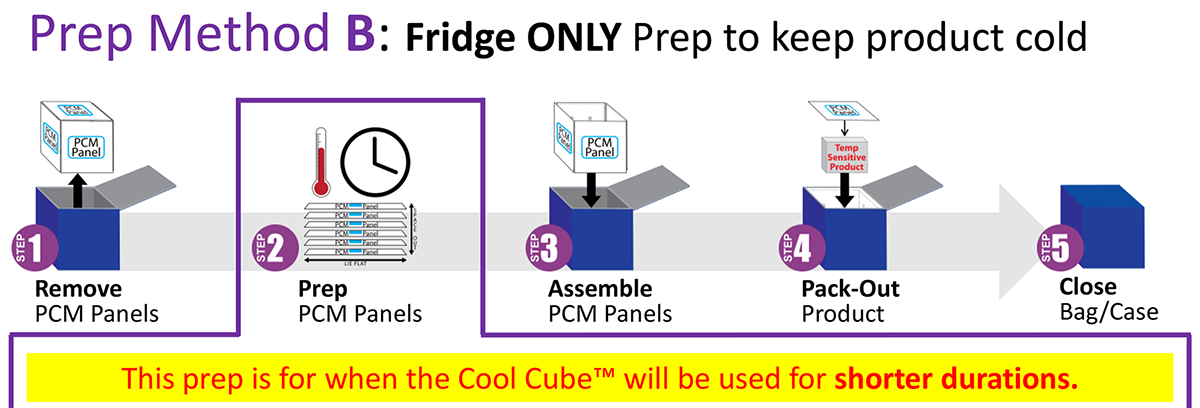

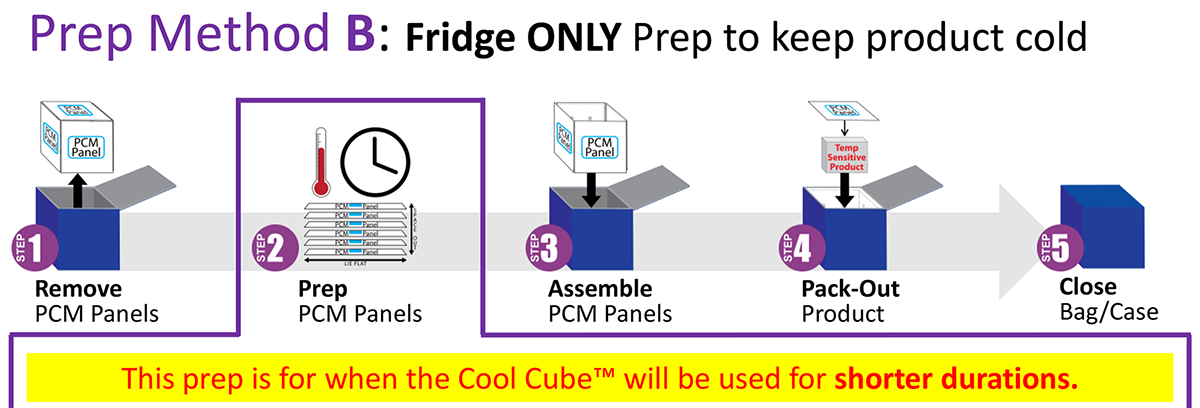

Refrigerated Prep Method B: Fridge Only Pack-Out Instructions

Panel Prep

2.1 Lay panels flat in a refrigerator for a minimum of 24 hours before use.

2.2 Shake panels to check the state of the PCM (phase change material inside the panel).

- If liquid…panel is at the fridge temp but above 5°C; anticipate shorter hold times.

- If solid…panel is at the fridge temp but below 4°C; ideal for maximum hold times.

- If solid/liquid combination…panel is at the fridge temp of 4-5°C; monitor time/temp.

In a refrigerator that maintains 4°C or below, the PCM will be solid (ideal for keeping product cold in warm/hot conditions). In a refrigerator that maintains 5°C or above, the PCM will be liquid. Although the PCM is liquid, the panel is at the temperature of the storage environment after 3 hours (i.e., stored in a 6°C fridge, the panels are at 6°C). Assembling the Cool Cube™ with liquid PCM panels (additional thermal mass) will help keep the product at its temperature, just for a shorter amount of time. Monitor Cool Cube™ temperature closely.

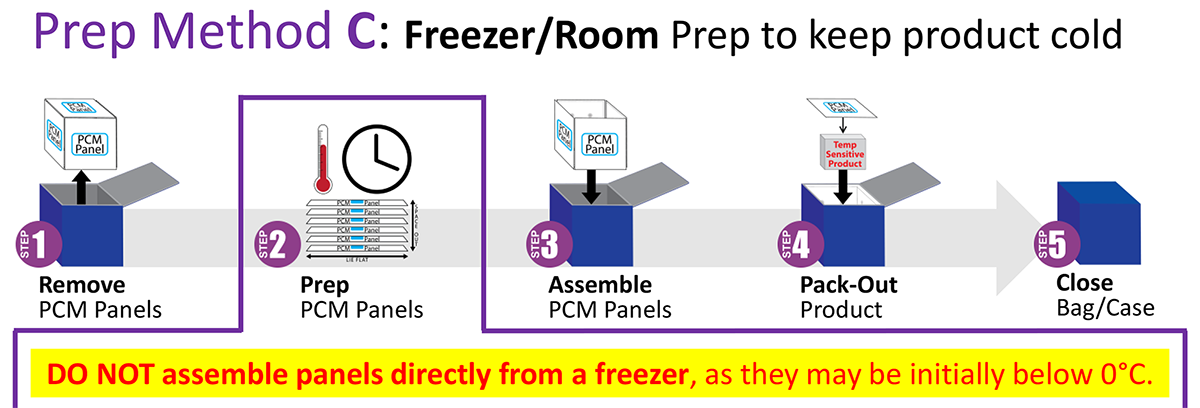

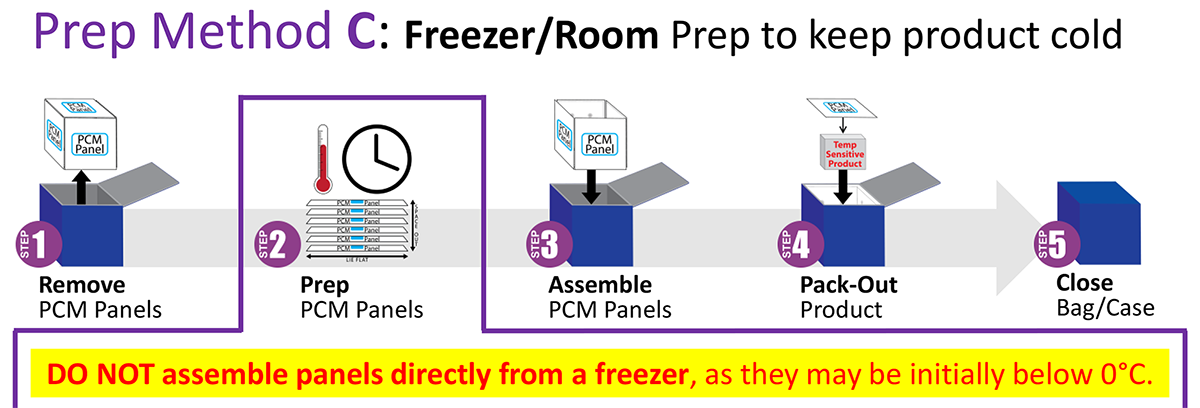

Refrigerated Prep Method C: Freezer to Room Pack-Out Instructions

Panel Prep

2.1 Lay panels flat in a freezer until all the PCM (phase change material inside the panel) turns solid. At -15°C/5°F the PCM will solidify in a couple hours.

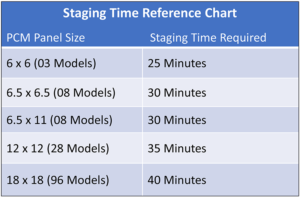

2.2 Transfer panels into a room temperature environment just before use to allow the PCM inside to rise to the appropriate operating temperature. Approximate times:

**Times based on a 22°C/72°F room.

2.3 Wipe off condensate. After frost turns to condensate, the panel is above 0°C.

2.4 Shake panels to verify the PCM is solid. If a little liquid is heard, it is at 4.5°C. If there is a lot of liquid, restart at step 2.1 to ensure the longest hold time. Using liquid PCM or panels with a solid/liquid combination decreases the hold time.

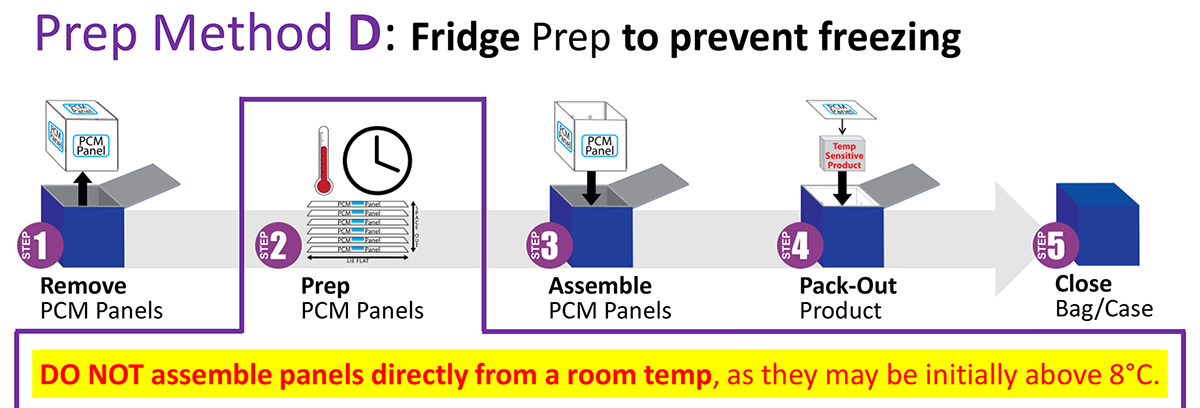

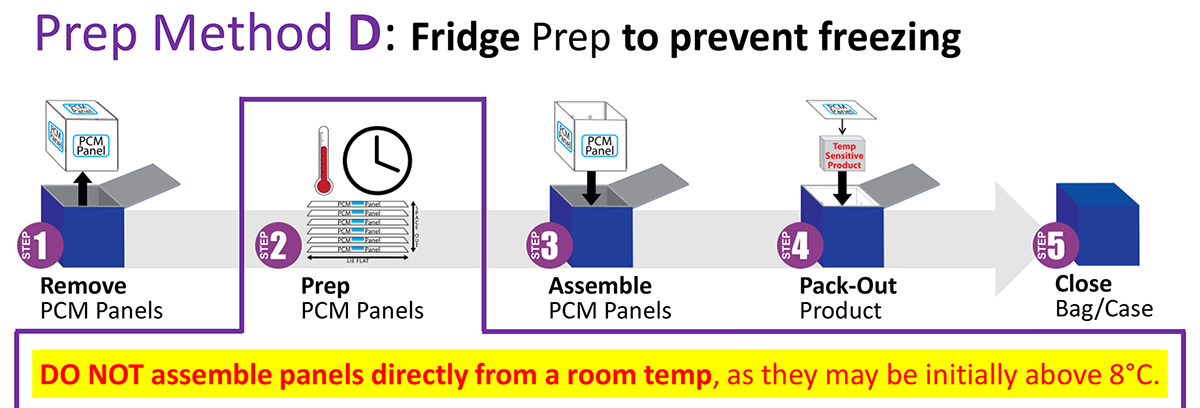

Series 4 Prep Method D: Fridge Only Pack-Out Instructions (to prevent freezing)

Panel Prep

2.1 Place panels in a fridge between 5° and 8°C for at least 24 hours before use so the PCM (phase change material inside the panel) is liquid.*

* Panels may be stored in the fridge until needed for assembly or the PCM solidifies. If a refrigerator maintains 5°C or above, the PCM within the panels will not get solid (the solidifying point is 4.5°C), keeping the PCM liquid indefinitely until pack-out. Liquid PCM panels will protect the product from freezing until the PCM becomes completely solid.

2.2 Shake panels to verify the PCM is liquid. If solid, restart at step 2.1 to ensure the longest hold time. Liquid PCM will prevent the product from freezing (at refrigerator temps) in extreme cold the longest. Using solid PCM or panels with a solid/liquid combination decreases the hold time.

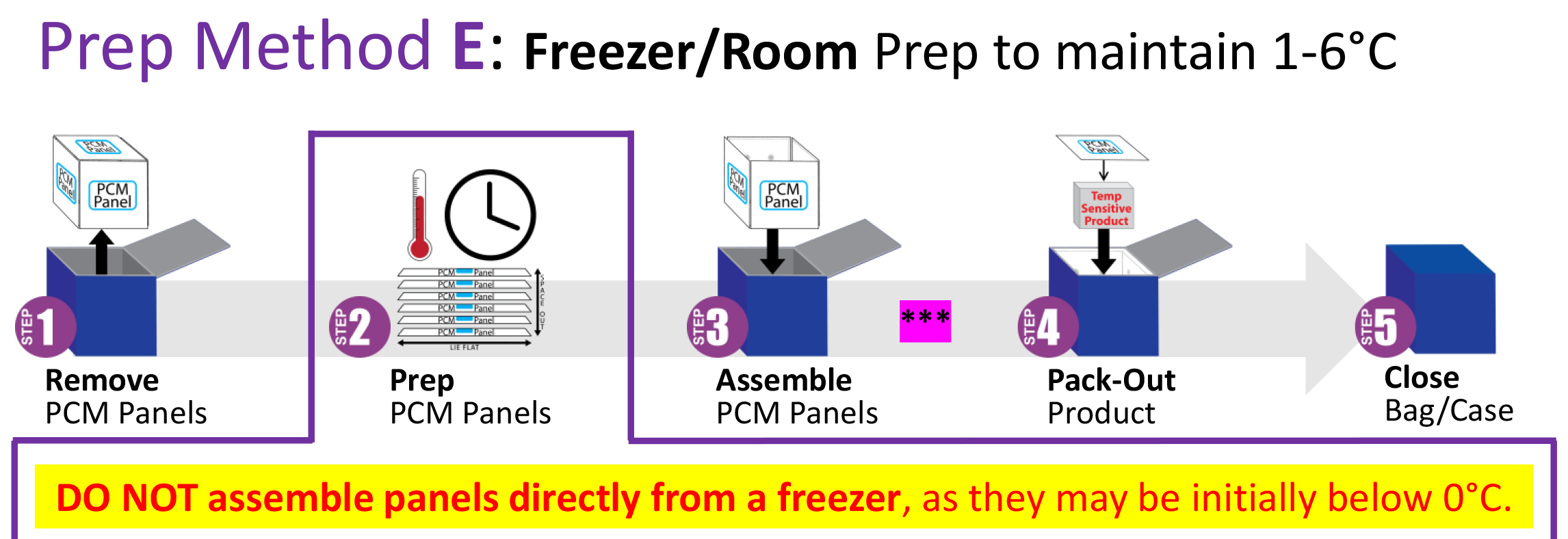

Refrigerator PCM Prep Method D: Fridge Only Pack-Out Instructions (to prevent freezing)

Panel Prep

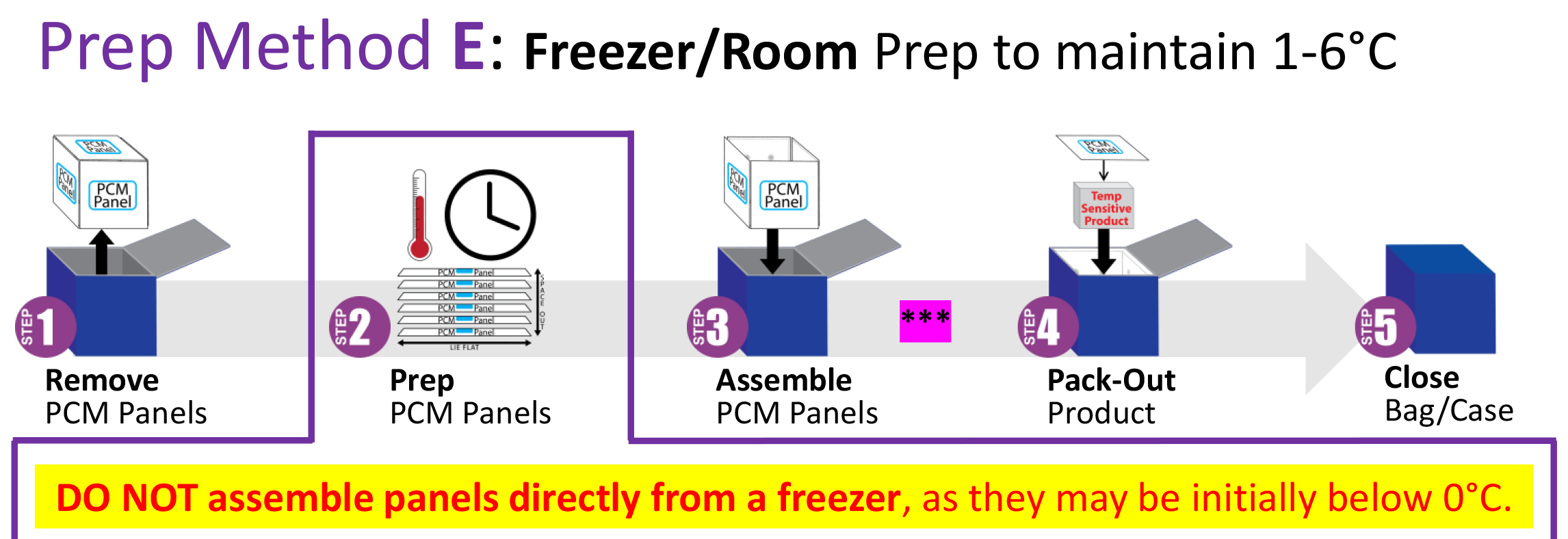

2.1 Lay panels flat in a freezer until all the PCM (phase change material inside the panel) turns solid. At -15°C/5°F the PCM will solidify in a couple hours.

2.2 Transfer panels into a room temperature environment just before use to allow the PCM inside to rise to the optimal 1°C. Approximate times:

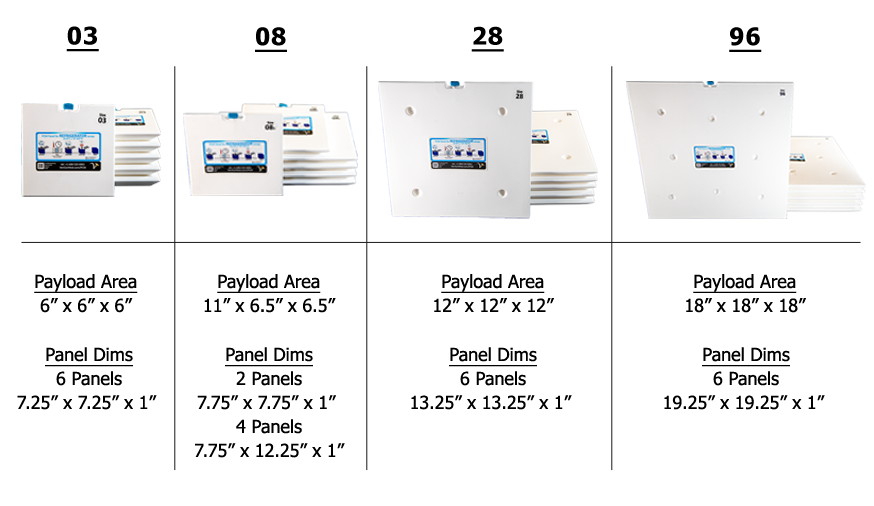

“03” size = 5 minutes

“08” size = 10 minutes

“28” size = 15 minutes

“96” size = 20 minutes

2.3 Wipe off condensate & shake.After frost turns to condensate, the panel is above 0°C. Shake panels to verify that the PCM is completely solid. If liquid is heard, re-freeze (Step 2.1) and proceed. Using liquid PCM decreases the hold time considerably.

After Step 3 (before pack-out), insert a thermometer and close to monitor when the Cool Cube™ gets to the 1°C mark. If below the 1°C mark, wait until it warms up to 1°C before packing out. To speed up the process, transfer panels into a room temperature environment for a couple of minutes and re-check. Pack-out at 1°C will ensure a maximum hold time between 1° and 6°C.