Answer:

The VIP System, or Vacuum Insulated Panel System, is a cutting-edge insulation technology used in Cool Cube products to provide superior thermal protection. VIPs are constructed with a core material surrounded by a vacuum-sealed barrier. This combination offers exceptional insulation, far more efficient than traditional materials like foam or polyurethane. Here’s how it works:

1. Vacuum Insulation:

The vacuum inside the panels minimizes heat transfer by significantly reducing conduction and convection, which are the primary ways heat is transferred. This vacuum environment is key to achieving the high thermal resistance, or R-value, that makes VIPs so effective at keeping heat out and cold in (or vice versa).

2. Efficiency:

VIPs can be up to five times more effective than conventional insulation, meaning they can maintain stable internal temperatures for much longer periods. This is particularly crucial in applications where temperature-sensitive products like vaccines, medicines, or biological samples are being stored or transported.

3. Durability:

VIPs are built to last. The protective outer wrapping around the core helps ensure that the vacuum remains intact, maintaining the panel’s high insulation performance for years. Even after five years, VIPs can retain up to 95% of their original insulating power.

4. Application in Cool Cubes:

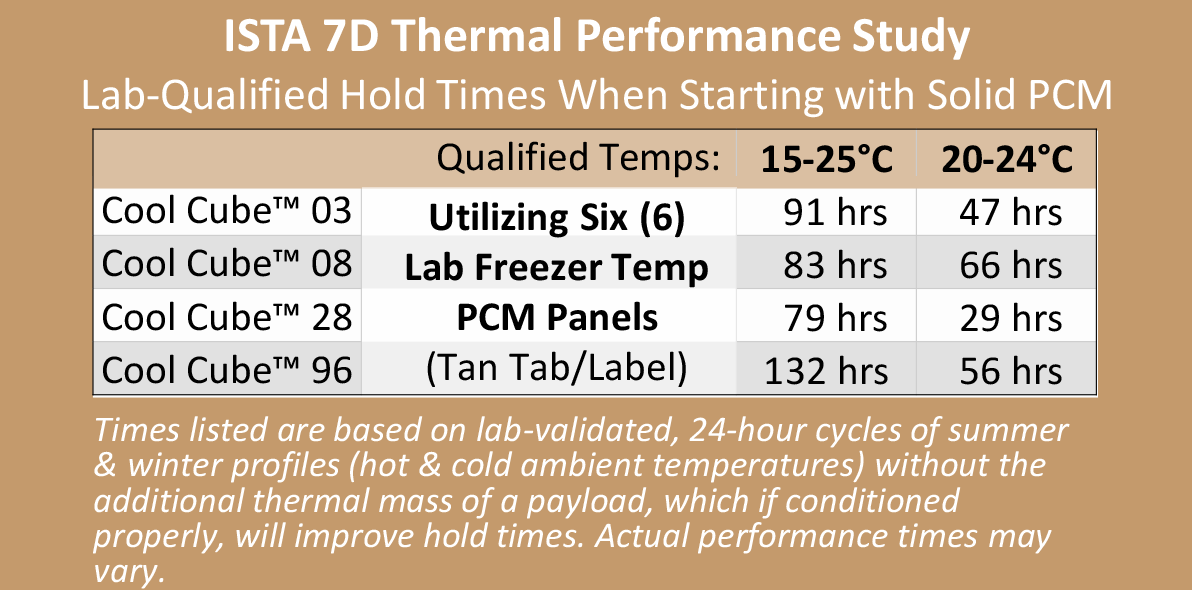

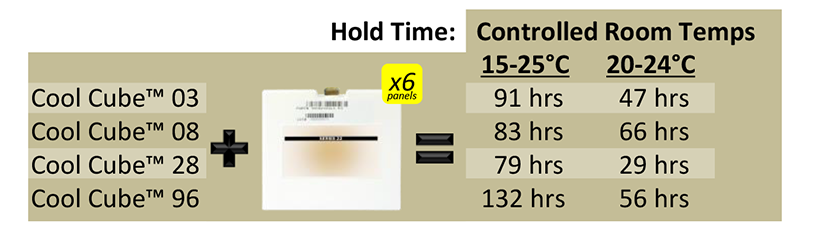

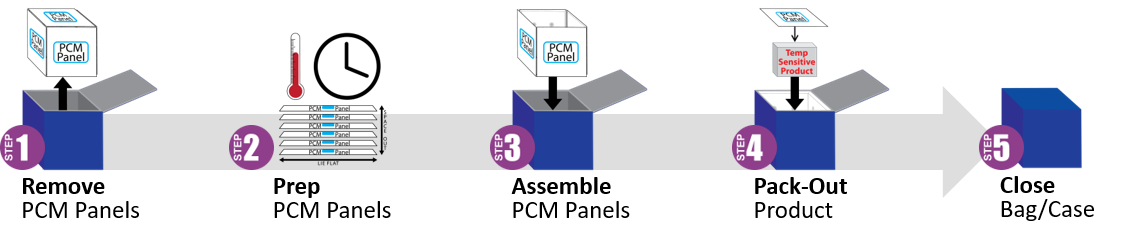

In Cool Cubes, the VIP System works in tandem with PCM (Phase Change Material) panels to maintain precise temperature control for long durations, even in extreme conditions. The VIP System is housed within the outer case of the Cool Cube, ensuring that internal temperatures remain stable without relying on electricity or ice.

By utilizing VIP technology, Cool Cubes offer reliable, energy-efficient temperature control for critical applications like medical transport, off-site vaccination efforts, and emergency preparedness.