Phase Change Materials (PCMs) are specialized substances used to maintain stable temperatures during the transportation and storage of sensitive products. Unlike traditional cooling methods, PCMs work by absorbing and releasing thermal energy as they transition between solid and liquid states. This unique property makes PCMs ideal for applications that demand precise temperature control, such as the storage of vaccines, medications, and other biological samples.

How PCM Works

PCMs operate by changing phases—from solid to liquid and back again—at specific temperatures. When PCM absorbs heat, it melts, but its temperature remains constant at its melting point until it fully liquefies. Conversely, when PCM releases heat, it freezes, holding steady at its freezing point until it solidifies. This phase transition enables PCMs to act as thermal buffers, keeping the internal environment of a container within a targeted temperature range, regardless of external conditions.

Advantages of PCM vs. Traditional Ice

Unlike ice, which freezes and melts at 0 °C (32 °F), PCMs can be formulated to melt and freeze at specific temperatures suited to different needs.

- Consistent Temperature Control: PCMs maintain stable temperatures without the fluctuations often seen with ice.

- Preventing Freezing Risks: Ice can cause temperatures to drop too low, risking freezing of products, or be too warm for really cold needs. PCMs are designed to hold specific temperatures safely above freezing or at ultra-cold levels, depending on the application.

- Even Temperature Distribution: Cool Cube™ PCM panels create a uniform temperature throughout the container, eliminating cold spots and ensuring that all parts of the payload are protected.

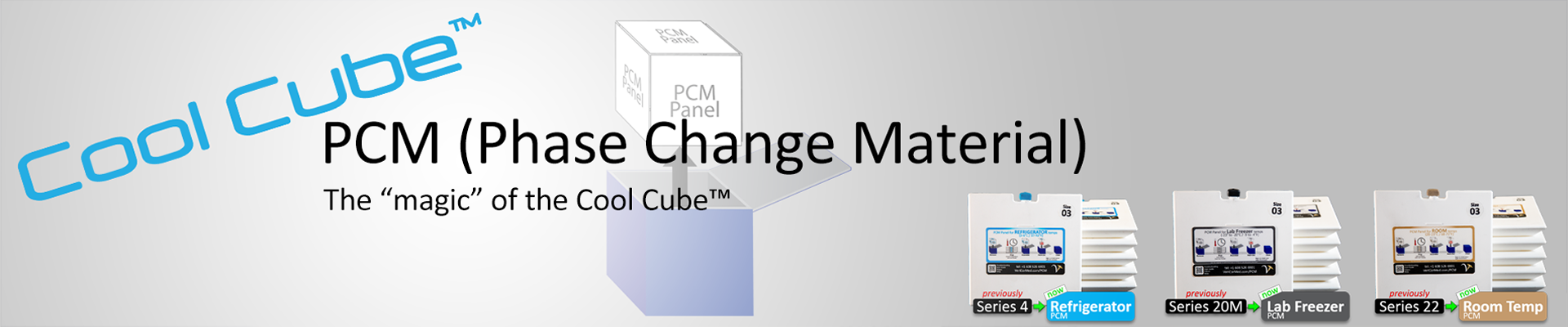

PCM in VeriCor Cool Cube™ PCM Coolers

VeriCor Cool Cube™ PCM Coolers harness the power of PCM to deliver reliable, passive temperature control across a range of applications. Each Cool Cube™ model uses PCM panels tailored to a specific temperature range:

- Refrigerator PCM (4.5°C/40.1°F): Designed for products needing refrigerator-like conditions, such as vaccines and medications.

- Room Temperature PCM (21.5°C/70.7°F): Ideal for items that must be kept at stable room temperature, such as certain pharmaceuticals.

- Lab Freezer PCM (-21.5°C/-6.7°F): Suited for ultra-cold storage, including certain biological samples and specialized medications.

By surrounding the cargo with PCM panels, each Cool Cube™ unit ensures even temperature distribution, safeguarding sensitive items from hot and cold extremes. Since PCMs maintain consistent, targeted temperatures without requiring external power sources, Cool Cube™ PCM Coolers provide dependable temperature control, even in challenging environments.

Why PCM Technology Matters

PCM technology offers a sustainable and reliable way to manage temperature-sensitive products. Its passive nature makes it a practical choice for remote locations, emergency situations, and transportation needs where dependable temperature control is essential. With VeriCor’s PCM-enabled solutions, you can trust that your temperature-sensitive products are safeguarded with the latest in temperature control innovation.

More Resources

Helping you is VeriCor’s purpose! If you can’t find what you are looking for in a timely manner, please call (608-526-6901) or email (info@vericormed.com) for assistance.